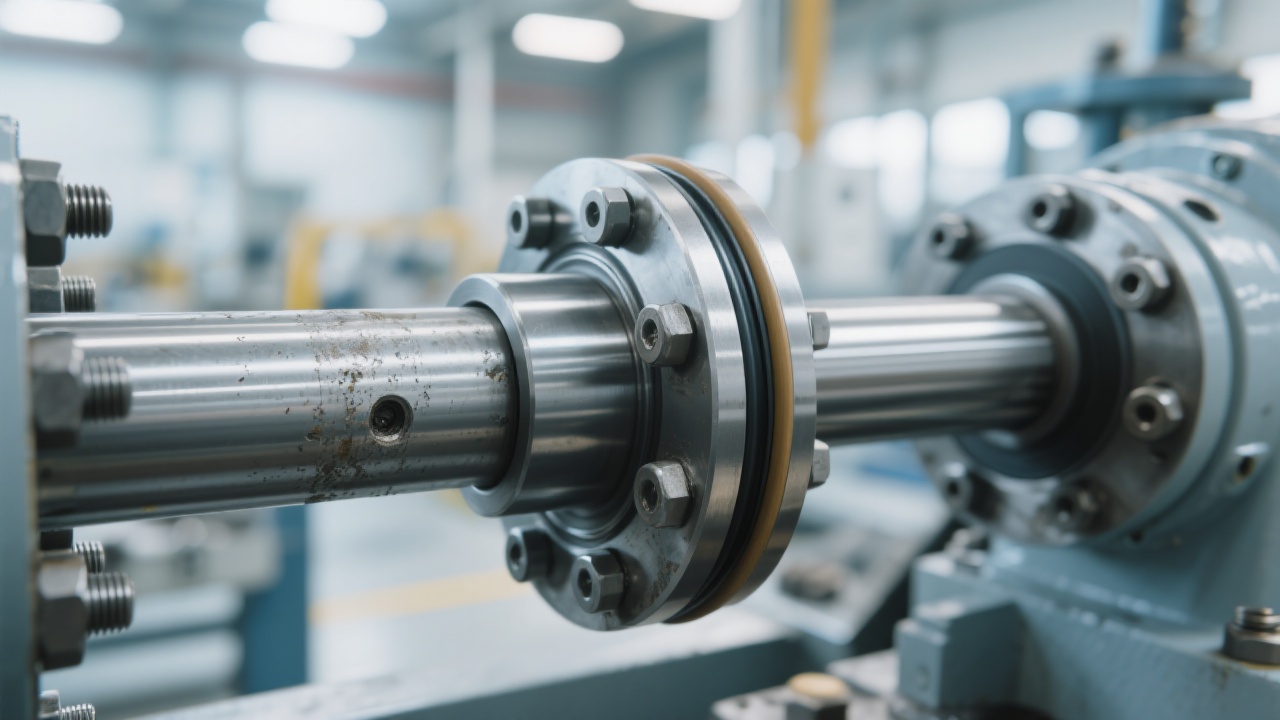

Screw oil presses are essential equipment in the oil extraction industry. Key components such as the screw shaft, cage, and vertical cake discharging mechanism play a crucial role in the overall performance of the press. The efficiency and longevity of these components directly affect the productivity and profitability of oil production.

High-wear-resistant materials possess several important technical characteristics, including hardness, toughness, and corrosion resistance. Hardness determines the material's ability to resist abrasion, while toughness allows it to withstand impact without fracturing. Corrosion resistance is vital in preventing material degradation in the presence of oil, moisture, and other substances.

| Material Characteristic | Impact on Equipment |

|---|---|

| Hardness | Enhances resistance to abrasion, reducing wear on the screw shaft and other components, thus extending equipment life. |

| Toughness | Allows the component to withstand sudden impacts and vibrations during operation, preventing fractures and maintaining stable operation. |

| Corrosion Resistance | Prevents rust and corrosion, especially in the presence of oil and moisture, ensuring the integrity of the component over time. |

The scientific selection of materials for the screw shaft, cage, and cake discharging mechanism has a significant impact on the equipment's service life. For example, a screw shaft made of high-hardness and high-toughness materials can withstand the high pressure and friction during the oil extraction process, reducing wear and tear. Similarly, the right material for the cage and cake discharging mechanism can improve the overall stability of the press and prevent premature failure.

Let's take a real - world case as an example. A certain oil processing plant replaced the original components of their screw oil press with those made of high - wear - resistant materials. After the replacement, the press's operation stability increased significantly. The maintenance frequency decreased from once every two months to once every six months, and the oil extraction efficiency increased by about 15%. This not only reduced the production cost but also improved the overall productivity.

Regular maintenance is crucial for extending the service life of the screw oil press. Some maintenance tips include regular cleaning of the components, lubrication of moving parts, and inspection of the wear status of the components. Additionally, having a good understanding of common faults and their prevention methods can help users avoid unexpected breakdowns. For example, checking the alignment of the screw shaft regularly can prevent uneven wear.

Our company offers excellent after - sales service and customer support. We have a professional team of technicians who can provide on - site maintenance and repair services. In addition, we offer training courses for users to help them better understand and operate the equipment. Our goal is to enhance the user experience and build long - term trust with our customers.

We have invited industry experts to share their experience and insights. They provide valuable advice on material selection, equipment operation, and maintenance. Also, we have compiled a list of frequently asked questions and their answers to improve the interactivity and practicality of this content.

Q: How often should I replace the screw shaft?

A: It depends on the usage frequency and the material of the screw shaft. Generally, if you use high - wear - resistant materials, the replacement interval can be extended to 1 - 2 years.

Q: Can I use normal materials instead of high - wear - resistant materials?

A: While normal materials may be cheaper initially, they will wear out faster, leading to more frequent maintenance and higher costs in the long run. High - wear - resistant materials are recommended for better performance and cost - effectiveness.

If you are looking for a high - efficiency and long - lasting solution for your screw oil press, click here to learn more about our high - wear - resistant materials and excellent after - sales service.