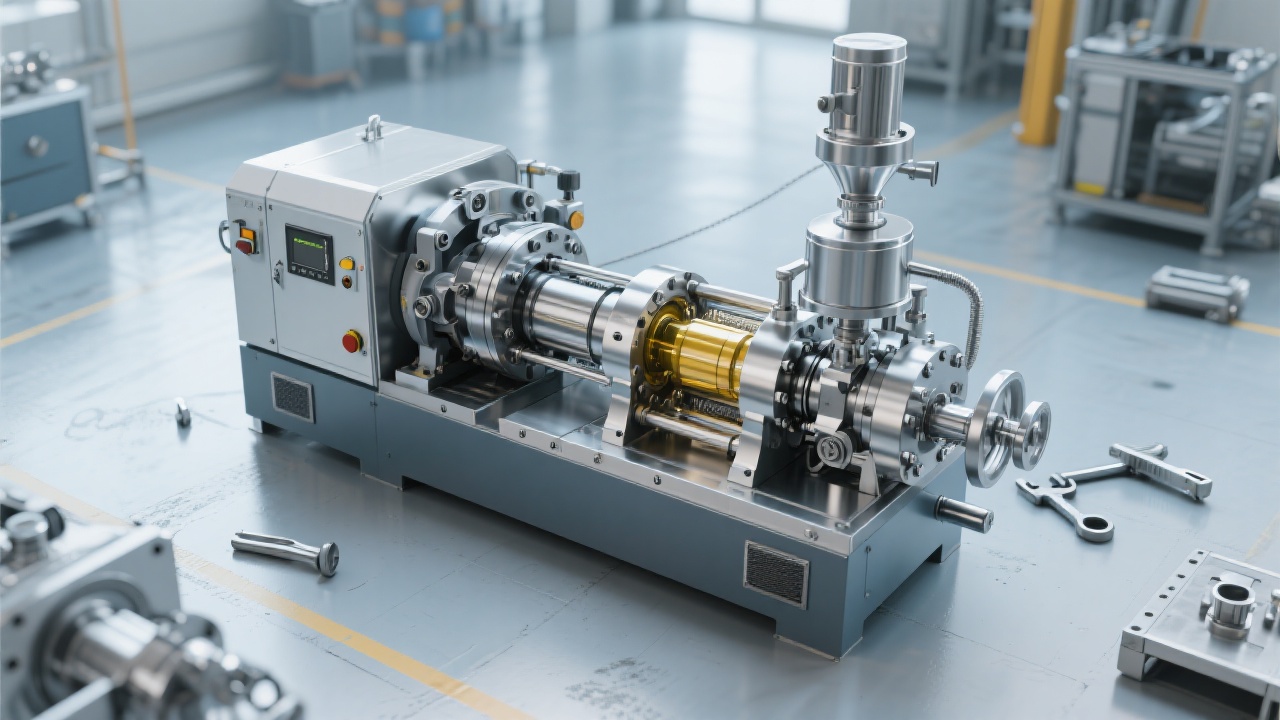

Wear-resistant materials have emerged as a game - changer in the world of screw oil presses. These materials bring significant technical value to the table, especially when it comes to enhancing the performance and longevity of the equipment. In industries such as food, chemical, and pharmaceutical, where continuous and efficient production is crucial, the use of high - quality wear - resistant materials can make a world of difference.

The material properties of key components like the screw shaft, cage, and cake discharge mechanism play a vital role in the overall operation of the screw oil press. For example, the screw shaft is constantly in contact with the raw materials during the pressing process. A wear - resistant screw shaft made of appropriate materials can ensure smooth operation and reduce the risk of jams. Research shows that a high - quality wear - resistant screw shaft can increase the service life of the oil press by up to 30% compared to traditional materials.

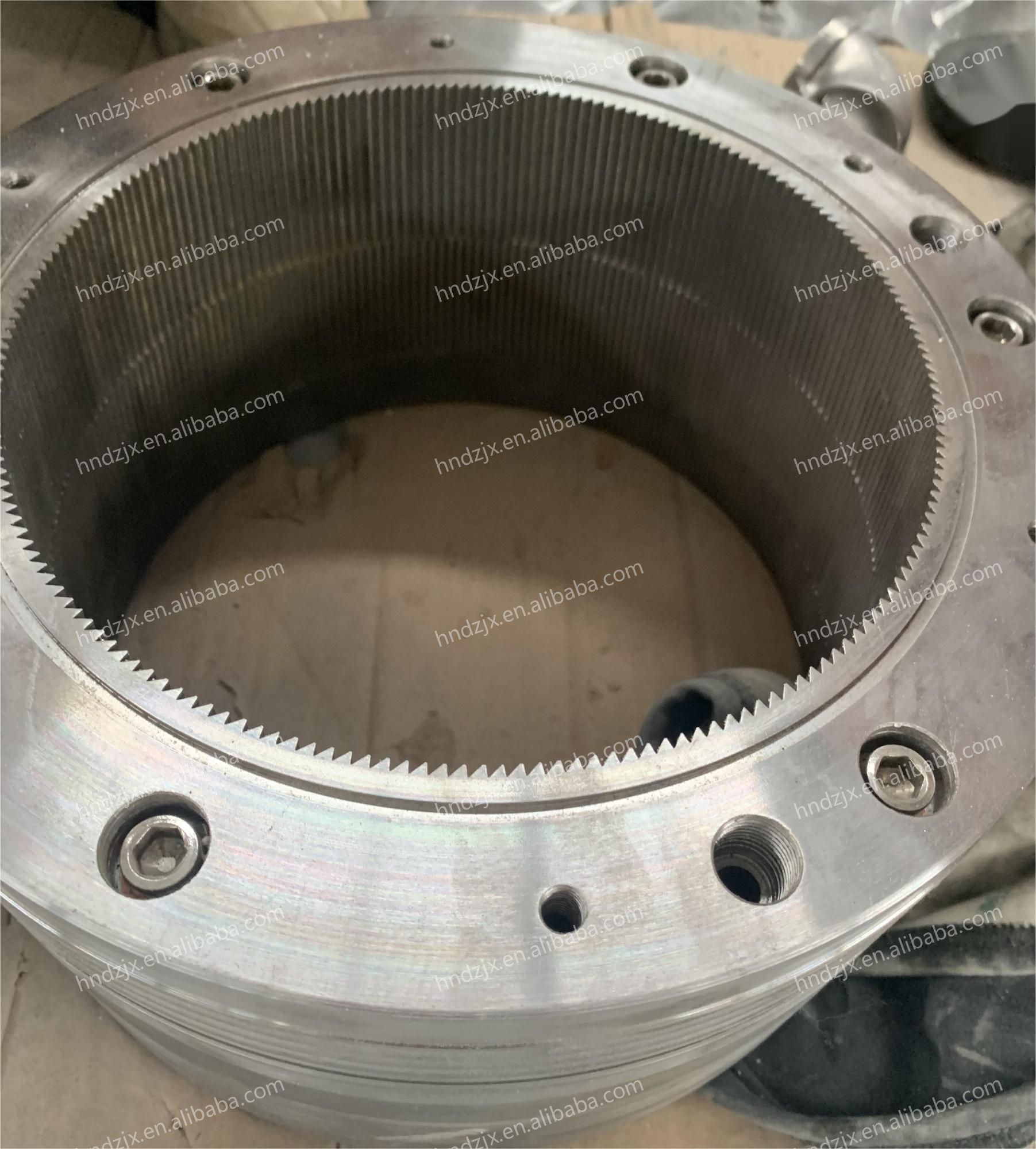

The cage also has a significant impact on the stability of the oil press. A well - designed cage made of wear - resistant materials can prevent the misalignment of internal components, thereby improving the overall stability of the equipment. Similarly, the cake discharge mechanism, which is responsible for removing the pressed cake, requires a material that can withstand repeated friction. Using wear - resistant materials in this component can reduce the wear and tear, leading to fewer breakdowns.

| Component | Traditional Material Service Life | Wear - resistant Material Service Life | Improvement Percentage |

|---|---|---|---|

| Screw Shaft | 1 - 2 years | 1.3 - 2.6 years | 30% |

| Cage | 1.5 - 2.5 years | 1.95 - 3.25 years | 30% |

| Cake Discharge Mechanism | 0.8 - 1.2 years | 1.04 - 1.56 years | 30% |

Let's take a look at some real - world examples. A food processing company was facing frequent breakdowns and high maintenance costs due to the wear and tear of their screw oil press components. After switching to high - wear - resistant materials in the screw shaft, cage, and cake discharge mechanism, they noticed a significant improvement. The downtime of the equipment was reduced by 40%, and the maintenance frequency decreased by 35%. This not only saved them a substantial amount of money but also increased their production efficiency.

Selecting the right wear - resistant material for each component is crucial. Factors such as the type of raw materials, the pressing process (hot or cold pressing), and the operating environment need to be considered. For example, in a hot - pressing process, materials with high heat resistance are required. We recommend consulting with our experts to choose the most suitable materials for your specific needs.

In addition to proper material selection, regular maintenance is also essential. Simple daily maintenance operations such as cleaning the components, checking for loose parts, and lubricating moving parts can significantly extend the service life of the oil press. Our company provides detailed maintenance guides to help you keep your equipment in top - notch condition.

Our after - sales service is a key factor in ensuring the long - term reliable operation of your oil press. We offer 24/7 technical support, and our team of experts is always ready to assist you with any problems you may encounter. Whether it's a minor issue or a major breakdown, we will provide timely and effective solutions.

Q: How much can I save on maintenance costs by using wear - resistant materials?

A: On average, you can expect to reduce maintenance costs by 30 - 35% compared to using traditional materials.

Q: Do I need to change my maintenance routine when using wear - resistant materials?

A: While wear - resistant materials reduce the frequency of maintenance, regular maintenance is still necessary. However, the maintenance operations may be less frequent and less complex.

Are you looking to enhance the performance and longevity of your screw oil press? Contact us now for a free technical consultation and let our experts help you choose the best wear - resistant materials and maintenance solutions for your business.