The double helical shaft meshing technology in oil presses represents a significant leap forward in the field of oil extraction. The basic structure consists of two helical shafts that are precisely meshed together. As the shafts rotate, they create a powerful squeezing force on the raw materials, whether it's peanuts, rapeseeds, or beans. This meshing mechanism allows for a more uniform and efficient pressure distribution during the pressing process. For instance, in a typical setup, the shafts can rotate at a speed of around 30 - 40 revolutions per minute, ensuring a continuous and stable pressing operation.

When it comes to different oilseeds like peanuts, rapeseeds, and beans, the double helical shaft meshing technology shows distinct pressing effects. Peanuts, with their relatively high oil content, can achieve an oil extraction rate of up to 45% - 50% using this technology. Rapeseeds, on the other hand, can reach an extraction rate of around 40% - 45%. Beans, which generally have a lower oil content, still benefit from the efficient pressing, with an extraction rate of approximately 15% - 20%. The adaptability of this technology to these different oilseeds lies in its ability to adjust the pressing pressure and speed according to the characteristics of the raw materials. For example, for softer oilseeds like beans, the pressure can be slightly reduced to prevent over - crushing and ensure a better oil - quality.

Compared with the traditional single - helical structure, the double helical shaft meshing technology has several prominent advantages. Firstly, the thrust is significantly enhanced. The double - helical design can generate a thrust that is 30% - 40% higher than that of a single - helical structure, ensuring a more forceful pressing of the oilseeds. Secondly, the oil discharge is much smoother. The meshing of the two shafts creates a more organized flow path for the oil, reducing the chance of blockage. In addition, the service life of the vulnerable parts is extended. Traditional single - helical structures often experience more wear and tear on the helical blades, but the double - helical design distributes the stress more evenly, increasing the lifespan of the parts by about 20% - 30%.

In different application scenarios such as food factories and small - scale processing plants, the double helical shaft oil press can meet both cold - pressing and hot - pressing needs. In a food factory, where the demand for high - quality and pure oil is high, the cold - pressing function can be used to extract oil without damaging the nutritional components of the oilseeds. The machine can maintain a low temperature of around 40 - 50 degrees Celsius during cold - pressing. For small - scale processing plants that may need to process a large amount of oilseeds quickly, the hot - pressing mode can be selected, which can increase the oil extraction efficiency by about 10% - 15% compared to cold - pressing.

This type of oil press features excellent energy - saving and environmental - friendly characteristics. It consumes about 20% - 30% less electricity compared to traditional oil presses, which not only reduces the operating cost but also contributes to a more sustainable production process. Moreover, it is designed with strict safety and compliance standards, meeting all the modern industrial requirements. For example, it is equipped with safety guards and automatic shutdown mechanisms in case of abnormal operation, ensuring the safety of the operators.

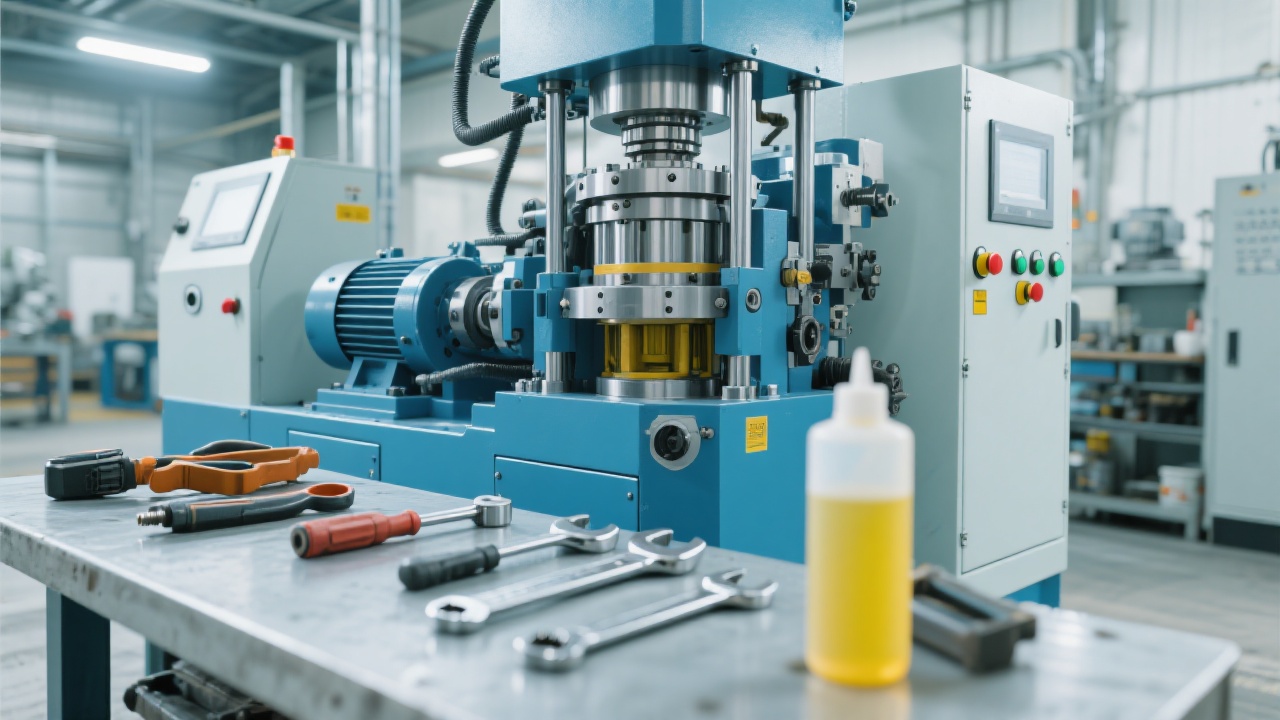

To ensure the long - term stable and efficient operation of the double helical shaft oil press, some operation and maintenance points should be noted. When operating, the feeding speed should be kept uniform, and the maximum feeding amount should not exceed the rated capacity of the machine. For daily maintenance, regular cleaning of the oil channels and inspection of the helical shafts for wear are necessary. It is recommended to lubricate the moving parts every 20 - 30 working hours to reduce friction and extend the service life of the machine.

Many users have provided positive feedback on the double helical shaft oil press. A small food processing factory in the Midwest of the United States reported that after using this oil press, their oil extraction efficiency increased by 25%, and the operating cost decreased by 20%. Another food company in Europe mentioned that the stable quality of the oil produced by this machine helped them expand their market share. These success stories demonstrate the reliability and practicality of the double helical shaft meshing technology in the oil - pressing industry.

| Question | Answer |

|---|---|

| Can this oil press be used for other oilseeds besides peanuts, rapeseeds, and beans? | Yes, it can be used for other oilseeds such as sunflower seeds and sesame seeds with appropriate adjustment of the pressing parameters. |

| What is the warranty period of the machine? | The warranty period is usually 1 - 2 years, and we also provide long - term after - sales support. |

Are you looking to optimize your oil - pressing process and reduce costs? Contact us at CTA - URL to get a customized oil - pressing solution and start your journey towards efficient and energy - saving production!