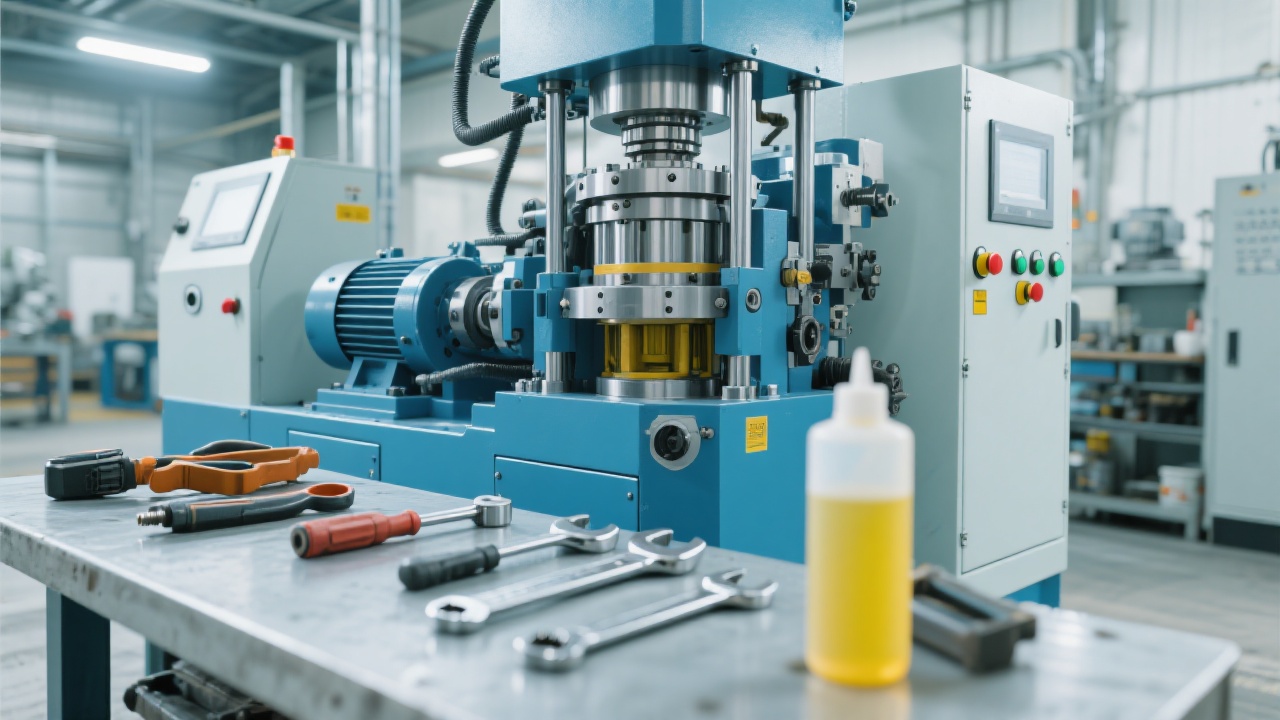

Operating a modern energy-efficient screw oil press isn’t just about turning the machine on—it’s about understanding how its innovative design translates into real-world efficiency gains for your production line. Whether you're processing peanuts, rapeseed, or soybeans, the right operation and maintenance routine can reduce energy consumption by up to 22% while boosting throughput by over 15% annually—according to field data from users in Southeast Asia and Eastern Europe.

The heart of this system lies in the dual-spiral shaft meshing mechanism—a patented configuration that ensures uniform pressure distribution across the entire oilseed bed. Unlike traditional single-shaft presses, where uneven compression leads to hotspots and mechanical stress, our design uses synchronized counter-rotating screws to apply consistent force, minimizing friction losses and maximizing oil yield per kilogram of raw material.

In cold-pressed applications (ideal for premium nut oils), this setup reduces thermal degradation by up to 40%, preserving flavor compounds and nutritional value. For hot-pressed operations (common in industrial vegetable oil plants), it maintains optimal temperature control within ±2°C during continuous runs—critical for meeting food-grade standards like ISO 22000 and HACCP.

| Oilseed Type | Avg. Yield Increase | Energy Savings (%) |

|---|---|---|

| Peanuts | +17% | 21% |

| Rapeseed | +19% | 24% |

| Soybeans | +15% | 20% |

To ensure long-term reliability, follow these steps:

Users who implement these practices report an average equipment lifespan increase of 3–5 years, with maintenance costs dropping by nearly 30% compared to standard operating routines.

As global demand shifts toward sustainable processing methods, companies that adopt efficient technologies not only lower operational costs but also strengthen their brand image among eco-conscious buyers—from EU food processors to Middle Eastern exporters seeking BRC-certified suppliers.

If you’re ready to unlock consistent performance and maximize ROI from your investment, we invite you to explore our full range of technical documentation and live support options.

Get Expert Guidance Today — Ask About Our Free Operational Audit Package

Download the Full Maintenance Checklist & Schedule a Live Demo