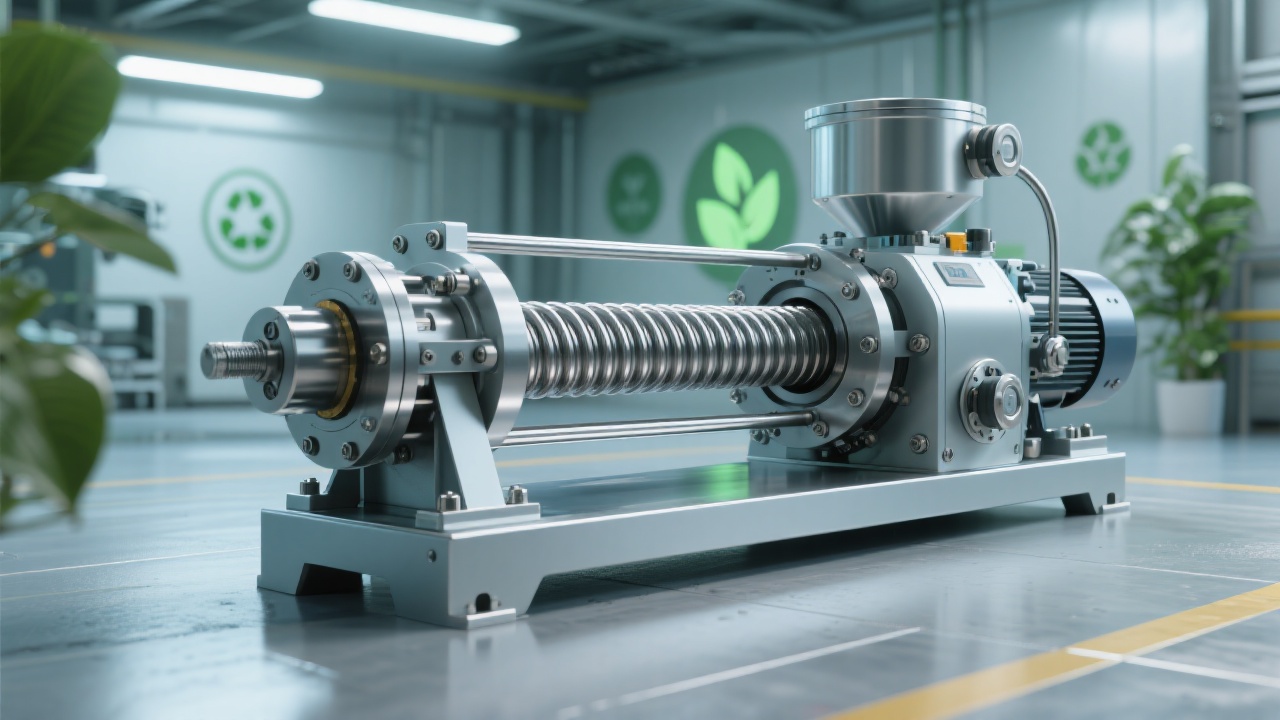

In the field of oil extraction, screw oil presses have long been a staple piece of equipment. However, traditional screw oil presses often face challenges such as oil - discharging blockage and difficult maintenance. This article will delve into the key designs of modern screw oil presses: the vertical cake - discharging mechanism and the segmented cage, and explore their working principles and practical application values in enhancing oil - discharging efficiency.

Traditional screw oil presses usually have a horizontal cake - discharging structure. During the oil - pressing process, residues tend to accumulate in the oil - discharging channels, leading to blockages. According to industry statistics, approximately 70% of traditional screw oil presses experience oil - discharging blockage problems within a year of operation. This not only reduces the oil - discharging efficiency but also requires frequent maintenance, increasing the overall production cost.

The vertical cake - discharging mechanism is a revolutionary design. Instead of the traditional horizontal way, it discharges the cake vertically. This design effectively reduces the probability of residue accumulation in the oil - discharging channels. The segmented cage, on the other hand, divides the cage into several segments. Each segment has a specific function, which can better control the pressure and flow direction during the oil - pressing process.

| Mechanism | Structural Feature | Working Process |

|---|---|---|

| Vertical Cake - Discharging Mechanism | Vertical cake - discharging design | During the oil - pressing process, the cake is discharged vertically, reducing residue accumulation in oil - discharging channels |

| Segmented Cage | Divided into several segments | Each segment controls pressure and flow direction during oil - pressing |

In practical applications, these two designs have brought significant improvements. The oil - discharging efficiency has been increased by about 30% compared to traditional equipment. At the same time, the maintenance frequency has been reduced by approximately 50%. The stability of the equipment has also been greatly enhanced. According to an engineer's feedback, after using the screw oil press with the vertical cake - discharging mechanism and the segmented cage, the equipment's continuous operation time has been extended from an average of 10 hours to 20 hours without major breakdowns.

In the food processing industry, safety and environmental protection are of utmost importance. The design of the vertical cake - discharging mechanism and the segmented cage fully complies with relevant industry standards. It reduces the generation of waste residues and energy consumption during the oil - pressing process. For enterprises, this not only helps to optimize the cold and hot oil - pressing processes but also improves production efficiency and long - term cost control. For example, a medium - sized oil - processing enterprise can save about 20% of production costs annually after adopting this new technology.

Some users may think that the new design is too complex and difficult to operate. In fact, with the improvement of technology, the operation of the screw oil press with the vertical cake - discharging mechanism and the segmented cage has become more user - friendly. The control system has been optimized, and operators can quickly master the operation skills through simple training.

If you want to learn more about how this design performs in actual working conditions and obtain the technical white paper, please click here.