In the realm of oil extraction, the efficiency and stability of screw oil presses are of paramount importance. Traditional screw oil presses often encounter issues such as oil drainage blockages and slag accumulation, which not only reduce the oil extraction efficiency but also increase the maintenance frequency and shorten the equipment lifespan. This article delves into the innovative design of the vertical cake discharging mechanism and segmented cage in high - efficiency, low - energy - consumption screw oil presses, aiming to provide a comprehensive understanding of how these technologies address industry pain points and enhance the overall performance of the equipment.

The screw oil press industry has long been plagued by problems related to oil drainage. In traditional equipment, the accumulation of slag can block the oil drainage channels, leading to reduced oil output and increased energy consumption. Moreover, frequent maintenance is required to clean the blocked channels, which not only increases the operating cost but also disrupts the production process. These issues have become significant obstacles to the efficient operation of enterprises in the food processing, chemical, and pharmaceutical industries.

The vertical cake discharging mechanism is a revolutionary design that effectively solves the problem of slag accumulation. By vertically discharging the cake, it prevents the slag from accumulating in the oil drainage area, ensuring smooth oil flow. According to engineers' experience and test data, this mechanism can reduce the slag accumulation by up to 80%, significantly improving the oil drainage efficiency. For example, in a food processing plant that uses traditional screw oil presses, the oil drainage channels need to be cleaned every 2 - 3 days. After adopting the vertical cake discharging mechanism, the cleaning frequency can be extended to once every 10 - 15 days.

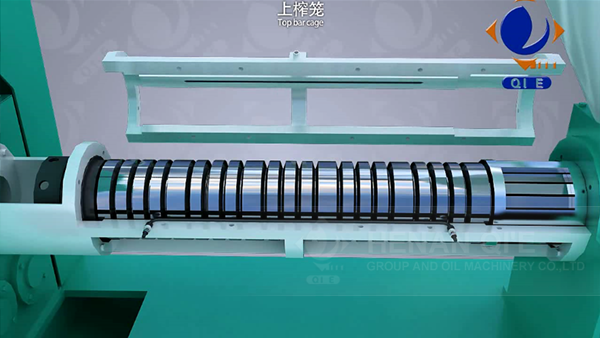

The segmented cage design further enhances the stability of the screw oil press. It divides the cage into several segments, which can better adapt to the different pressures and forces during the oil extraction process. This design reduces the wear and tear of the cage, extends the equipment lifespan, and improves the overall stability of the machine. Test results show that the segmented cage can increase the equipment lifespan by at least 30%. In a chemical enterprise, the traditional cage needs to be replaced every 6 - 8 months. After using the segmented cage, the replacement cycle can be extended to 9 - 12 months.

The vertical cake discharging mechanism and segmented cage are equally effective in both cold and hot pressing processes. In the cold pressing process, they ensure the purity of the oil by reducing the slag content. In the hot pressing process, they can withstand high temperatures and pressures, maintaining the stability of the oil extraction process. This versatility makes the screw oil press suitable for a wide range of applications in different industries.

In addition to improving the oil extraction efficiency, the innovative design of the vertical cake discharging mechanism and segmented cage also helps enterprises comply with industry safety and environmental protection standards. By reducing the energy consumption and waste generation, it contributes to the sustainable development of enterprises. For example, in the pharmaceutical industry, strict safety and environmental protection standards are required. The new design of the screw oil press can help pharmaceutical enterprises meet these standards, ensuring the quality and safety of their products.

In conclusion, the vertical cake discharging mechanism and segmented cage are significant technological innovations in the screw oil press industry. They not only solve the industry pain points but also provide enterprises with a more efficient, stable, and compliant production solution. If you are interested in learning more about this innovative technology and its application in your industry, please visit our product page and download our technical white paper at /products/high-efficiency-low-energy-spiral-oil-press-machine-–-intelligent-energy-saving-oil-extraction-solution.html. Discover how our screw oil presses can revolutionize your oil extraction process.

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)