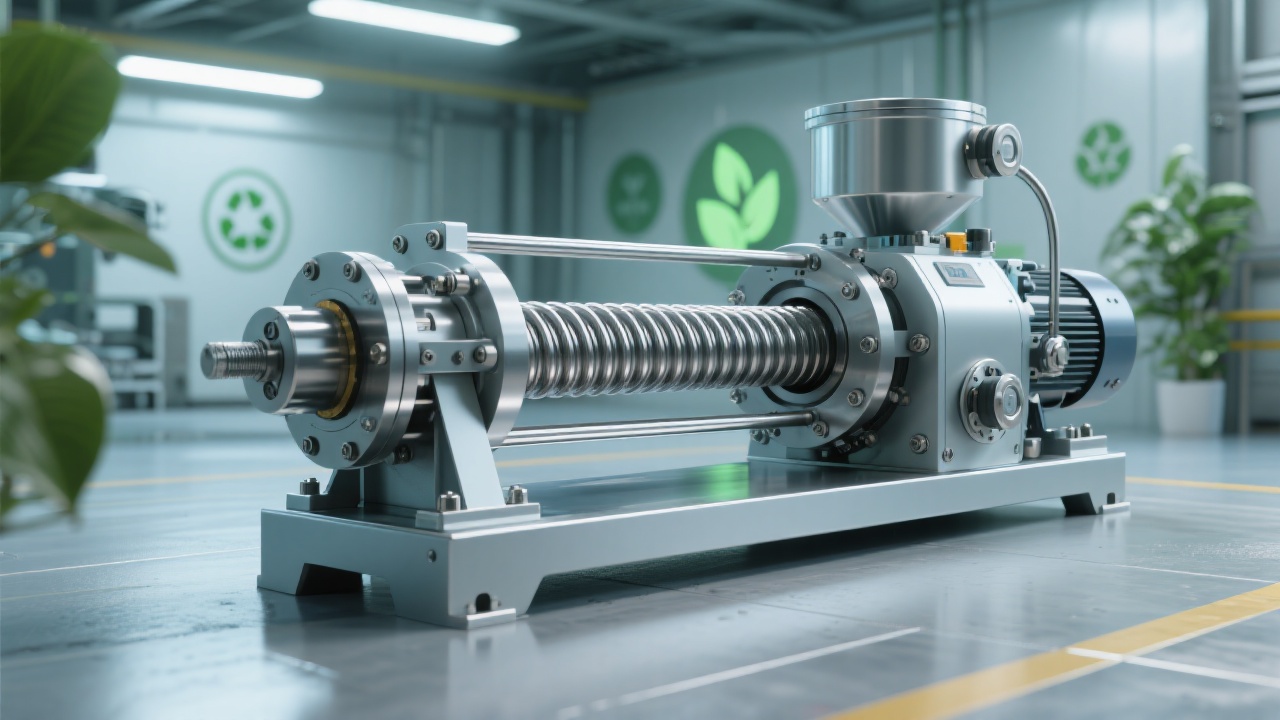

In the food processing industry, the stable and efficient operation of screw oil presses is crucial for both production efficiency and oil quality. Traditional screw oil presses often encounter common issues such as poor oil drainage and slag accumulation, which can lead to frequent breakdowns, increased maintenance costs, and reduced equipment lifespan. This article delves into how the innovative design of the vertical cake discharging mechanism and segmented cage can address these pain points and enhance the performance of screw oil presses.

Conventional screw oil presses in the food processing industry face several challenges. For example, oil drainage can be impeded due to the design of the oil outlet, leading to a decrease in the efficiency of oil extraction. Additionally, the accumulation of slag inside the press can cause blockages, which not only affects the quality of the extracted oil but also requires frequent maintenance. According to industry data, nearly 60% of traditional screw oil presses experience oil drainage problems within the first year of operation, and about 40% suffer from slag accumulation issues, resulting in an average of 15-20 days of downtime per year for maintenance.

The vertical cake discharging mechanism and segmented cage are designed to work in tandem to solve the problems of traditional oil presses. The vertical cake discharging mechanism is designed to ensure smooth cake discharge, preventing the accumulation of slag at the discharge end. The segmented cage, on the other hand, allows for better oil drainage by providing a more open structure. Together, they improve the overall efficiency of the oil extraction process and reduce the likelihood of blockages.

The vertical cake discharging mechanism operates by using gravity to facilitate the smooth removal of the pressed cake. This design ensures that the cake is discharged quickly and completely, reducing the chance of slag accumulation. The segmented cage is designed with a series of segments that allow oil to flow freely through the press. This structure is highly adaptable to different types of oilseeds, such as peanuts and rapeseeds. For example, in tests with peanut oil extraction, the new design increased the oil extraction efficiency by 10-15% compared to traditional presses.

"The vertical cake discharging mechanism and segmented cage are revolutionary designs in the screw oil press industry. They not only improve the efficiency of oil extraction but also reduce the maintenance requirements, which is a significant advantage for food processing enterprises." - An engineer from the R & D team

In real-world applications, the use of the vertical cake discharging mechanism and segmented cage has shown significant improvements in the stability of screw oil presses. A food processing plant in [Location] reported that after installing the new equipment, the maintenance frequency decreased by 50%, and the equipment's lifespan was extended by at least 3 years. The plant also saw a reduction in energy consumption by approximately 20% due to the more efficient operation of the press.

The new design of the screw oil press also helps enterprises meet international food safety and environmental protection standards. The efficient oil extraction process reduces the use of chemicals and energy, which is in line with the trend of sustainable development. Moreover, the reduced maintenance requirements mean less waste generation, contributing to a more environmentally friendly production process.

In summary, the vertical cake discharging mechanism and segmented cage offer several key advantages for screw oil presses in the food processing industry. They improve oil extraction efficiency, reduce maintenance costs, enhance equipment stability, and help enterprises meet international safety and environmental standards. If you are in the food processing industry and are looking for a more efficient and sustainable solution for your screw oil press, this innovative design is definitely worth considering.

Do you have any questions about the operation of your screw oil press? Have you ever encountered problems with slag accumulation? Leave your comments below and share your experiences.

Download the technical whitepaper to master the secrets of efficient oil extraction and see how this innovative design can transform your food processing operations. Click here to download now