In the food processing and chemical industries, traditional screw oil presses often encounter a series of common faults that significantly impact production continuity. For instance, problems like slag accumulation and low efficiency are widespread. Slag accumulation can lead to equipment blockages, forcing production to halt for cleaning and maintenance. This not only disrupts the production schedule but also incurs additional costs. Low efficiency means longer processing times and lower output, which directly affects the overall productivity of the enterprise. According to industry statistics, traditional oil presses may experience blockages once every 10 - 15 production cycles, and the average production efficiency is only about 60 - 70% of the theoretical value.

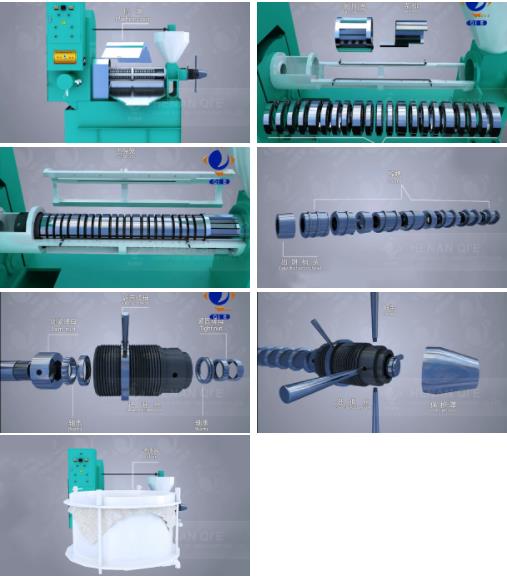

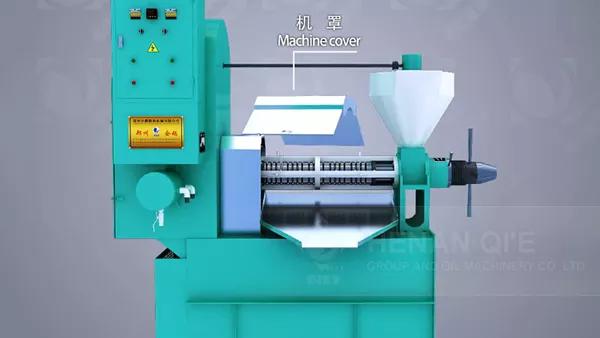

The vertical cake discharging mechanism is a revolutionary design in screw oil presses. Its working principle is based on the vertical movement of the cake, which effectively solves the problem of oil and slag discharge. When the oil - pressing process is completed, the vertical cake discharging mechanism quickly and smoothly discharges the cake, preventing the accumulation of slag in the oil - pressing chamber. This design ensures that the oil can flow out smoothly, reducing the probability of blockages. Compared with traditional designs, the vertical cake discharging mechanism can increase the oil discharge efficiency by about 30 - 40%.

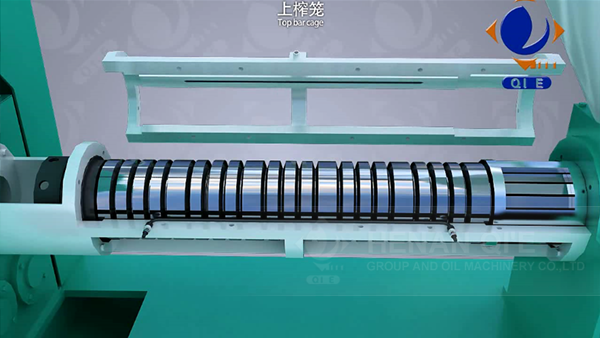

The segmented cage is another key innovation. Its segmented structure provides better support and guidance for the oil - pressing process. Each segment of the cage can be adjusted independently, allowing for more precise control of the oil - pressing process. This structure effectively reduces the friction between the screw and the cage, improving the overall stability of the equipment. At the same time, it also helps to evenly distribute the pressure, ensuring that the oil is extracted more efficiently. The segmented cage can reduce the wear of the screw by about 20 - 30% compared to traditional cages.

Through actual tests, the improvement effects of these two innovative designs are obvious. In terms of oil discharge smoothness, the new - designed screw oil press has increased the oil discharge flow rate by 40 - 50% compared with traditional models. In terms of maintenance intervals, the maintenance cycle has been extended from once every 10 - 15 production cycles to once every 25 - 30 production cycles. The following table shows the specific data comparison:

| Indicator | Traditional Oil Press | New - designed Oil Press |

|---|---|---|

| Oil Discharge Flow Rate (L/min) | 20 - 30 | 30 - 45 |

| Maintenance Cycle (Production Cycles) | 10 - 15 | 25 - 30 |

This screw oil press with innovative designs has strong adaptability to both cold - pressing and hot - pressing processes. In the cold - pressing process, the vertical cake discharging mechanism and the segmented cage can ensure that the oil is extracted at a low temperature, preserving the nutritional components of the oil. In the hot - pressing process, they can withstand high - temperature and high - pressure environments, ensuring stable oil extraction. Moreover, this equipment complies with international safety and environmental protection standards, which provides users with reliable quality assurance. As an engineer said, "This oil press is a great innovation that can meet the needs of different production processes."

The application of these innovative designs brings comprehensive benefits to users. Firstly, it reduces operating costs. With less frequent maintenance and higher oil extraction efficiency, the cost per unit of oil production is significantly reduced. Secondly, it extends the service life of the equipment. The reduced wear and tear on the components ensure that the equipment can operate stably for a longer time. Finally, it improves the overall production efficiency. The smooth oil discharge and stable operation of the equipment enable continuous and efficient production. If you want to learn more about how these innovative designs perform in actual working conditions, click here to get the technical white paper.