In the modern edible oil extraction industry, process efficiency and equipment reliability are paramount. Traditional screw oil presses often struggle with residual oil blockage and cake accumulation due to inefficient discharge mechanisms, resulting in frequent downtime and increased maintenance costs. This article explores the innovative design of a vertical cake discharge mechanism paired with a segmented retaining cage that substantially mitigates these challenges, guaranteeing a more stable operation and superior oil yield.

Conventional screw presses typically rely on horizontal or inclined cake discharge paths, where gravity alone is insufficient to expel pressed cakes efficiently. This leads to oil pooling and residue accumulation within the press chamber, elevating pressure irregularities and mechanical wear. Industry data indicate that up to 35% of maintenance downtime in traditional presses is attributable to sediment clogging and inefficient cake removal, thus impairing continuous production and inflating operational expenses.

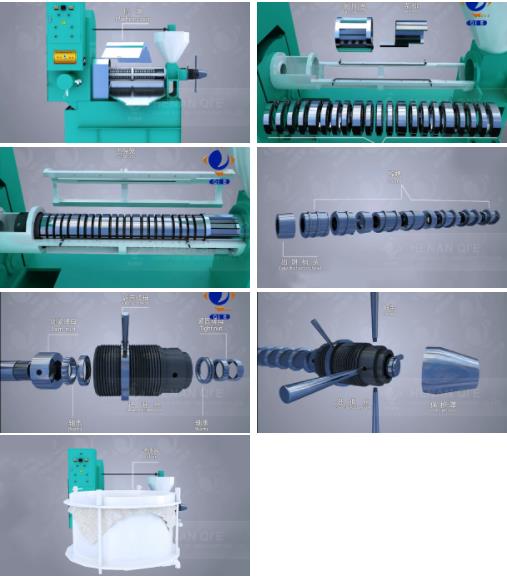

The vertical cake discharge mechanism introduces a fundamentally different approach by utilizing a gravity-assisted downward flow complemented by self-cleaning functionalities embedded in the structural design. This system reorients the cake discharge path vertically, ensuring that solid residues naturally fall away from the pressing zone without retention. Key advantages include:

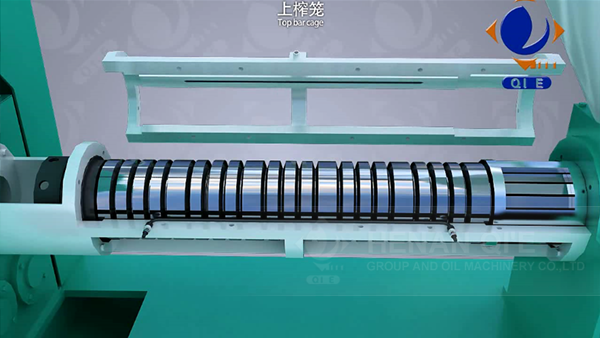

Complementing the vertical discharge mechanism, the segmented retaining cage is engineered to apply consistent and uniform pressure on the oil cake layers within the press channel. By dividing the cage into precise segments, the design addresses common challenges such as uneven compression and choke points that exacerbate residue accumulation. Technical highlights include:

| Feature | Benefit |

|---|---|

| Segmented cage sections | Ensures uniform material squeezing, reducing localized blockages. |

| Optimized material selection | Minimizes wear and friction, extending component lifespan by 25%. |

| Precision engineering tolerance | Prevents bypass flow, maximizing oil extraction efficiency. |

The integration of the vertical cake discharge mechanism and segmented retaining cage shows significant operational improvements in various oilseed cold and hot pressing contexts, particularly with challenging materials like peanut and rapeseed. Field trials conducted over six months demonstrate:

These advancements empower edible oil producers to optimize production workflows, reduce energy consumption, and secure economic benefits over long-term equipment operation cycles.

Curious about how this technology performs under your production conditions? Discover the full technical whitepaper and real-world case studies here.