In today’s competitive edible oil industry, ensuring oil purity while optimizing operational costs is paramount for mid-size producers. The integration of multi-stage precision filtration systems in fully automatic hot and cold oil pressing machines offers a transformative approach to meeting these challenges. This article explores the technical principles behind multi-stage filtration, its impact on oil quality, and how it significantly reduces equipment maintenance frequency and labor expenses.

Multi-stage precision filtration strategically applies different filtration media in succession to remove impurities of varying sizes and types from extracted edible oil. Typically, the system is broken down into three to five filtration phases, each designed to target specific contaminants:

| Filtration Stage | Purpose | Target Impurities | Typical Filter Media |

|---|---|---|---|

| Stage 1 | Coarse filtration | Solid residues, seed hulls | Metal mesh or wire screens (50-100 μm) |

| Stage 2 | Medium filtration | Fine particles, suspended solids | Activated carbon, cellulose filters (10-50 μm) |

| Stage 3 | Precision filtration | Micro impurities, colloids | Membrane filters (1-10 μm) |

This layered approach guarantees superior oil clarity while preserving essential nutrients such as tocopherols and fatty acids. Compared to single-stage filtration, multi-stage systems can reduce residual impurities by over 90%, directly contributing to increased oil shelf life — a critical quality factor for both producers and consumers.

By effectively filtering oils stepwise, multi-stage precision filtration significantly reduces the accumulation of debris and contaminants inside equipment pipelines and heat exchangers. This translates into several operational advantages:

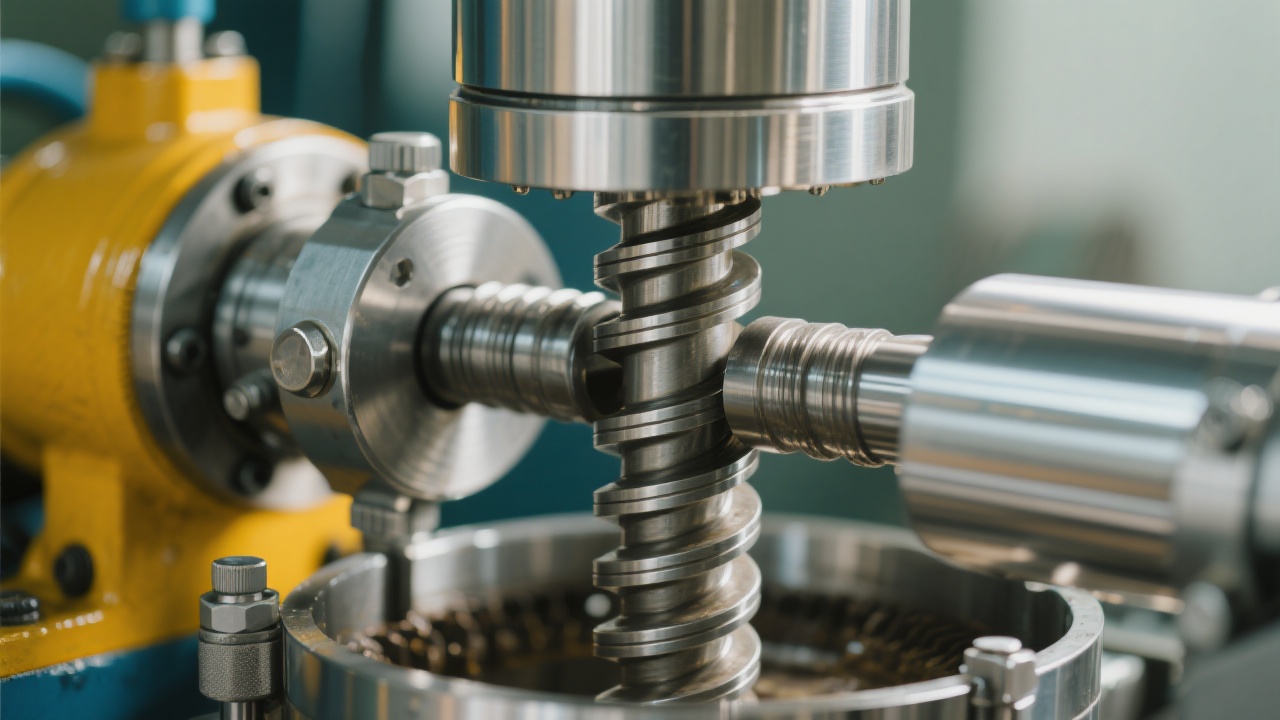

The following infographic illustrates the oil flow through multi-stage filtration within automatic hot/cold pressing equipment, emphasizing impurity removal at each stage and resulting oil purity improvement.

Incorporating advanced filtration technology does not merely address operational efficiency; it also significantly enhances oil quality. By removing oxidative agents and impurities, multi-stage filtration helps maintain nutrient integrity and inhibits rancidity. Studies suggest that oils processed with multi-stage filtration retain up to 15% more antioxidants compared to traditional filtration, ultimately resulting in safer and more nutritious products with prolonged freshness periods.

Mid-sized edible oil manufacturers adopting multi-stage filtration systems benefit from both tangible cost savings and elevated brand reputation. The combination of consistent high-quality output, reduced downtime, and efficient labor allocation empowers these companies to stand out in a crowded market.

Moreover, the scalable design of multi-stage filtration units allows for customization depending on production volume, seed types, and oil characteristics — ensuring flexible integration into existing pressing lines with minimal disruption.