For edible oil producers aiming to meet global safety standards and enhance product shelf life, multi-stage filtration isn’t just an upgrade—it’s a necessity. Unlike single-pass filters that leave behind fine particulates, modern systems use layered precision to remove impurities at every stage, ensuring cleaner oil, better taste, and improved nutritional retention.

A typical multi-stage system includes three key phases:

| Stage | Filter Mesh Size | Purpose |

|---|---|---|

| Coarse Filter | 100–200 µm | Removes large solids like seeds, husks, and sediment. |

| Fine Filter | 10–50 µm | Captures micro-particles, phospholipids, and gums. |

| Ultra-Fine Filter | 1–5 µm | Eliminates trace metals, free fatty acids, and residual odors. |

According to a 2023 study by the International Journal of Food Engineering, this tiered approach improves total suspended solids (TSS) removal by up to 94% compared to conventional methods—leading to oil with fewer oxidation markers and extended shelf life.

“After installing our multi-stage system, we saw a 30% reduction in customer complaints about rancid taste—and our oil now lasts 6 months longer on shelves.” — Li Wei, Operations Manager, Jiangsu Golden Seed Oil Co.

One client in Vietnam reported a 40% decrease in manual filter cleaning time after switching from batch filtering to automated multi-stage units. Meanwhile, lab tests showed their refined palm oil retained over 97% of tocopherols, crucial antioxidants often lost during aggressive processing.

In contrast, traditional single-filtration setups require frequent maintenance and still leave behind particles that accelerate degradation. With multi-stage systems, manufacturers reduce downtime by up to 25% and cut labor costs by 18%, according to a 2022 survey of 30 mid-sized oil plants across Southeast Asia.

These improvements aren’t just technical—they translate directly into brand trust. Buyers in EU and GCC markets increasingly demand transparent, science-backed production processes. A clean, stable oil product means fewer returns, higher margins, and stronger B2B relationships.

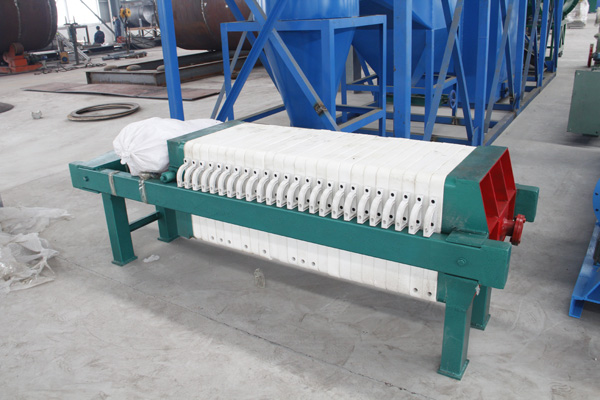

Whether you’re using cold-pressed or hot-pressed extraction, our energy-efficient, fully automatic multi-stage filtration systems are designed for seamless integration into existing lines.

Explore Energy-Efficient Cold & Hot Press Oil Machines Now