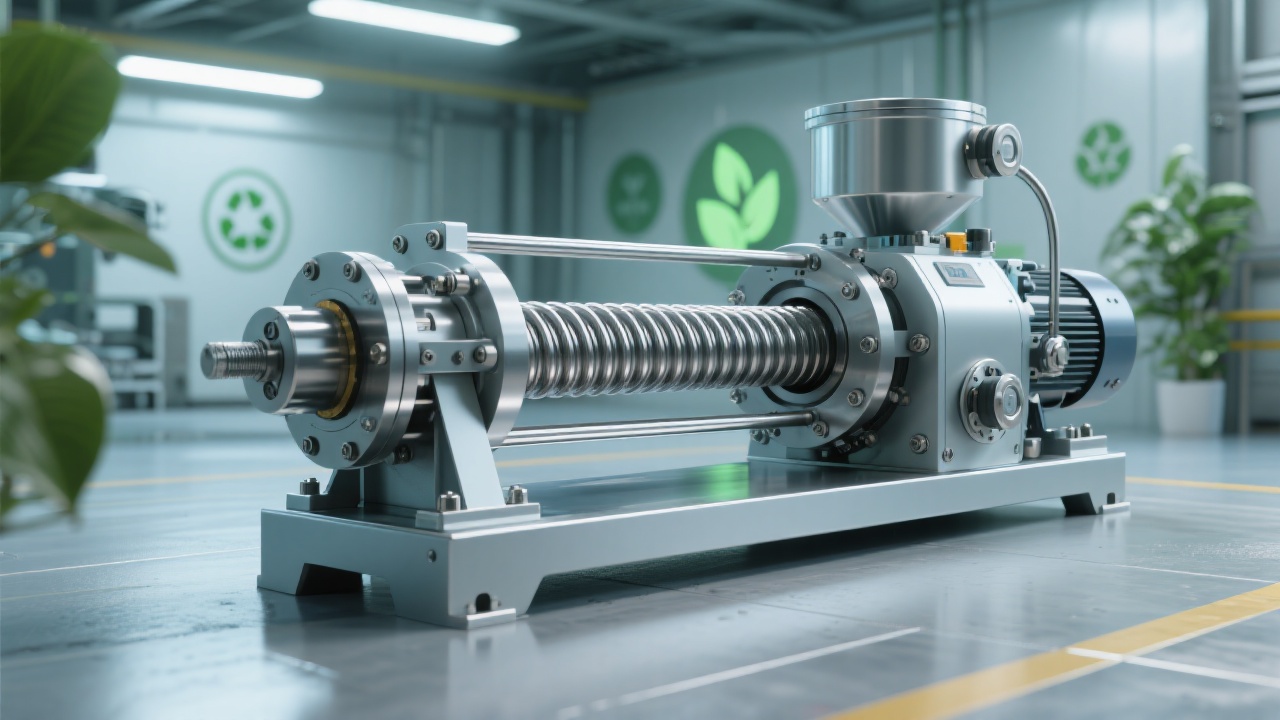

For food processing and chemical manufacturers, the efficiency of screw oil expellers directly impacts production stability, maintenance costs, and overall profitability. Traditional designs often suffer from oil residue buildup due to inefficient discharge mechanisms—leading to frequent downtime, higher labor costs, and inconsistent output quality.

The key lies in two innovative structural components: the vertical cake discharge mechanism and the segmented holding cage. These aren’t just incremental upgrades—they redefine how material flows through the press chamber.

By integrating a vertically aligned discharge system, the unit eliminates dead zones where oil and solids accumulate. Combined with a segmented holding cage that maintains uniform pressure distribution across the screw shaft, this design ensures consistent throughput—even under variable feed conditions or temperature shifts between cold and hot pressing cycles.

| Performance Metric | Before Upgrade | After Upgrade |

|---|---|---|

| Maintenance Frequency (per month) | ~8 times | ~5.5 times |

| Process Stability (±% oil yield) | ±7% | ±2.5% |

| Equipment Lifespan Extension | Standard (3–4 years) | Extended by ~25% (4–5 years) |

In a case study conducted at a vegetable oil plant in Indonesia, implementing these innovations led to a 30% reduction in unplanned maintenance hours over six months. Operators reported fewer clogs during high-viscosity feedstock runs—common in cold-pressed rapeseed or sunflower oil production—and improved consistency in final oil clarity.

This isn't just about reducing wear—it's about enabling reliable cold-pressing for premium oils while maintaining thermal efficiency for industrial-grade applications like palm or soybean processing. The adaptability makes it ideal for facilities aiming to diversify product lines without investing in multiple machines.

As global regulations tighten around energy use and waste management, especially in EU and North American markets, equipment must meet ISO 14001 and OSHA standards. Our optimized design reduces mechanical friction and minimizes oil sludge generation—supporting cleaner operations and easier compliance audits.

Manufacturers using this technology have seen measurable improvements in their ESG reports, particularly in metrics related to resource efficiency and workplace safety.

If you're looking to reduce operational costs, improve process reliability, and future-proof your facility against evolving environmental expectations, now is the time to evaluate how modernized screw expeller designs can transform your workflow.

Download our free technical white paper with detailed test results from 12 international clients—including before-and-after performance comparisons and installation tips.

Get the Full Technical White Paper