In industrial oil extraction—whether for food processing, pharmaceuticals, or chemical manufacturing—the reliability of your equipment directly impacts production uptime, compliance, and long-term ROI. Traditional spiral oil presses often suffer from frequent clogging due to poor oil discharge design and inefficient material flow paths. This leads to costly shutdowns, inconsistent yields, and increased labor demands.

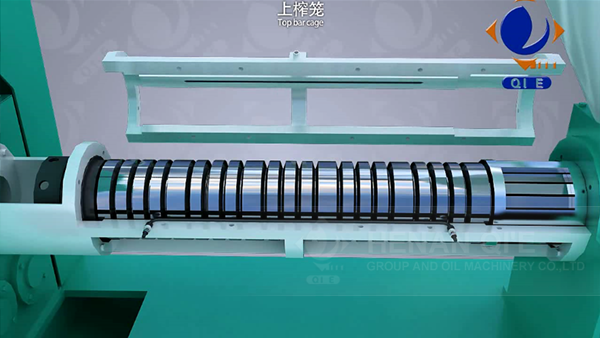

Our latest generation of spiral oil presses integrates two critical innovations that address the root causes of maintenance issues:

These features aren’t just theoretical—they’ve been validated through real-world operation. At a sunflower oil plant in Ukraine, after installing our new press with these components, maintenance intervals extended from every 48 hours to over 120 hours, saving an estimated $2,800 per month in labor and downtime costs.

“We used to clean the machine every shift. Now we do it once a week—and even then, it’s mostly just inspection.”

—— Alexei Petrov, Plant Manager, Ukrainian Agro Processing Co.

The benefits go beyond just fewer breakdowns. With less manual intervention required, operators can focus on quality control rather than cleaning. Additionally, higher oil yield improves sustainability metrics—a key factor for ESG reporting in EU and North American markets.

If you’re managing a facility where consistent throughput matters—or if your team spends too much time on routine maintenance—you’ll want to understand how this design translates into real savings. We’ve compiled case studies, test logs, and customer feedback into a detailed technical white paper that shows exactly what happens when you move from reactive to proactive maintenance.

Get the full technical white paper with data from 30+ installations worldwide.

Download Technical White Paper →