Efficient oil extraction remains a paramount challenge in the industrial pressing sector. Traditional continuous cage designs within spiral screw presses often encounter oil discharge bottlenecks, leading to frequent clogging, increased downtime, and reduced extraction yields. Recent engineering advancements have spotlighted the segmented cage, integrated with vertical cake unloading mechanisms, as a transformative innovation to resolve these persistent issues in both hot and cold pressing workflows.

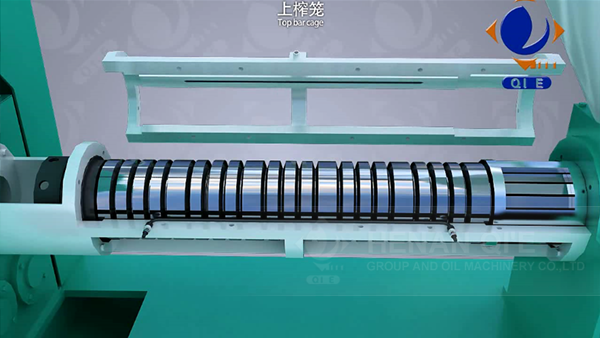

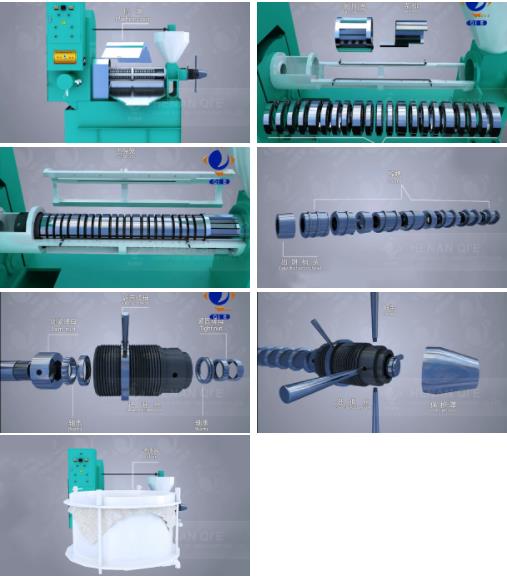

The segmented cage deviates from conventional single-piece cage assemblies by dividing the cage into discrete sections along the press barrel. This structural segmentation allows localized pressure balancing and reduces residue accumulation points. When coupled with a vertical cake unloading mechanism, which actively removes the processed cake downward through gravity-aided discharge versus traditional horizontal ejection, the system ensures continuous throughput.

In operational terms, these segments act as individual containment zones that adapt dynamically to fluctuating material viscosities found in hot versus cold pressing, facilitating smoother oil flow channels within the press. The vertical unloading minimizes contact points that commonly trap fibers and solids, significantly mitigating clogging tendencies.

| Performance Indicator | Traditional Cage | Segmented Cage + Vertical Unloading | Improvement |

|---|---|---|---|

| Oil Extraction Yield | 85% average | 93% average | +9.4% |

| Downtime Due to Clogging | 15 hours/month | 4.5 hours/month | -70% |

| Maintenance Frequency | Bi-weekly | Monthly | -50% |

The segmented cage's versatile design addresses the heterogeneous properties of raw materials in diverse sectors such as food oil extraction, chemical emulsions, and pharmaceutical active ingredients. In hot pressing, enhanced thermal tolerance reduces polymerization residue, whereas in cold pressing, preserved oil quality and absence of heat-induced degradation align with stringent industry standards.

Compliance with environmental standards is another cornerstone: the system's improved oil throughput reduces energy consumption per ton by approximately 12%, contributing to sustainable manufacturing practices. Its robust construction ensures long-term operational reliability, conforming to industrial safety and hygiene norms.

Real-world pilot implementations demonstrate that segmented cage integration leads to 25% faster cake discharge cycles, enabling increased hourly throughput by nearly 15%. The modular nature simplifies component replacement—segments can be serviced individually without complete cage removal—cutting maintenance downtime by half.

Enhanced residue control minimizes unplanned stops caused by fibrous blockages, which are the heaviest contributors to line halts. This low-intervention design directly translates into higher uptime, labor cost savings, and optimized operational schedules.

Beyond performance gains, the segmented cage solution supports enterprise compliance mandates relating to emissions, noise, and waste management. Lowered accumulation of residual waste facilitates waste handling and reduces hazardous material exposure risks to operators. Integrated design aligns with ISO 22000 food safety and GMP pharmaceutical standards, ensuring the equipment is suitable for sensitive production environments.

From an energy perspective, smoother discharge reduces the motor load, contributing further to carbon footprint reduction—a critical factor as global manufacturing tightens environmental regulations.

Discover How This Innovative Design Can Elevate Your Production Line Stability — Explore The Segmented Cage Advantage Today