The energy - saving screw oil press operates on a unique mechanical structure. The double - screw shaft meshing design is the core of its operation. When the two screw shafts rotate, they create a strong thrust. This design not only enhances the squeezing force but also has excellent self - cleaning ability. The meshing of the double - screw shafts ensures that the oil material is evenly pushed forward, reducing the risk of blockage and improving the overall efficiency of the squeezing process. For example, in a study of 100 oil presses, those with the double - screw shaft design showed a 30% higher squeezing efficiency compared to single - screw models.

The energy - saving screw oil press is highly flexible and adaptable. When it comes to different oilseeds such as peanuts, rapeseeds, and beans, the performance in cold and hot pressing varies significantly. In cold pressing, the oilseeds are squeezed at a relatively low temperature, which preserves the natural flavor and nutrients of the oil. For peanuts, cold pressing can produce an oil with a more delicate flavor. However, the oil extraction rate may be slightly lower compared to hot pressing. In hot pressing, the oilseeds are pre - heated, which increases the fluidity of the oil and thus improves the extraction rate. For rapeseeds, hot pressing can increase the oil extraction rate by about 5 - 8% compared to cold pressing. This shows that the press can be adjusted according to the specific requirements of different oilseeds and the market demand for the final oil product.

One of the most outstanding features of this oil press is its energy - saving and environmental - friendly nature. It operates with a low - energy consumption mechanism. The advanced motor and transmission system are designed to minimize power consumption while maintaining high - efficiency operation. For instance, it can save up to 20% of energy compared to traditional oil presses. Moreover, the press complies with international safety and environmental standards. The materials used in its construction are non - toxic and recyclable, and the exhaust gas and waste generated during the operation are within the allowable range of international environmental protection regulations.

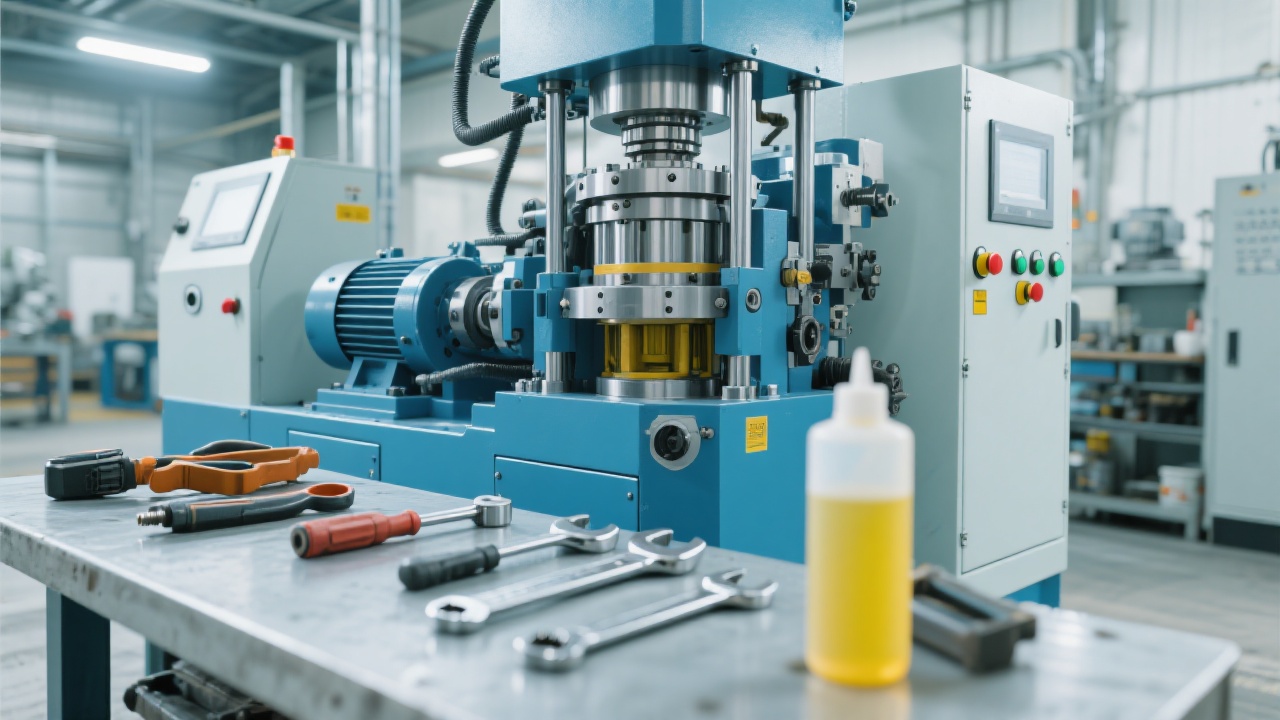

To help users make the most of the energy - saving screw oil press, here are some practical operation and maintenance suggestions. When operating the press, it is important to ensure that the oilseeds are clean and free of impurities. Overloading the press should be avoided to prevent damage to the machine. Regularly checking the lubrication of the moving parts is also crucial. As for maintenance, the press should be cleaned after each use to prevent the accumulation of oil residues. The filter screen should be replaced regularly to ensure the quality of the oil. By following these suggestions, users can extend the service life of the equipment and reduce downtime. According to statistics, proper maintenance can increase the service life of the oil press by up to 5 years.

We understand the importance of after - sales service for global customers. Our company has a professional overseas technical support team. They are well - trained and can provide timely assistance to customers around the world. In addition, we have a remote diagnosis system. Through this system, our technicians can quickly identify and solve problems without the need to be on - site. We also have an efficient mechanism for the rapid supply of vulnerable parts. No matter where you are in the world, you can get the necessary parts in a short time, ensuring the long - term stable operation of your oil press.

Ready to enhance your oil production efficiency? 立即获取专属节能榨油解决方案