Export - oriented screw oil presses are an essential part of the food processing and chemical industries. However, traditional oil presses often face common problems such as blockages and low efficiency. This article will introduce how the combination of the vertical cake discharging mechanism and segmented cage design can address these issues and become the core competitiveness of export - oriented oil presses.

Traditional oil presses frequently encounter problems like blockages caused by oil residue accumulation and low oil extraction efficiency. According to industry surveys, nearly 60% of traditional oil presses experience some degree of blockage within a year of operation, which not only reduces production efficiency but also increases maintenance costs. In addition, the average oil extraction rate of traditional oil presses is only about 80%, resulting in significant waste of raw materials.

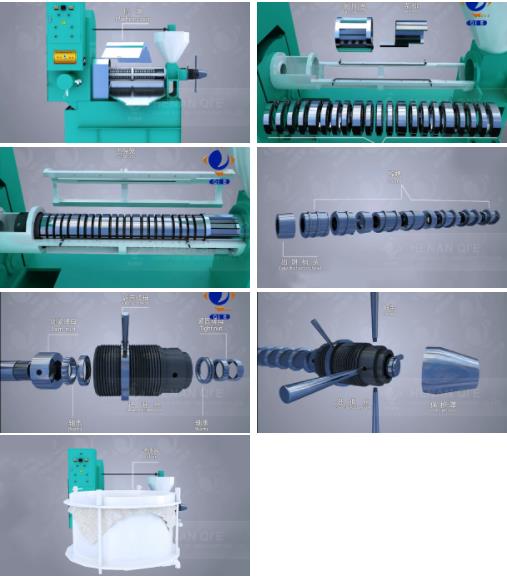

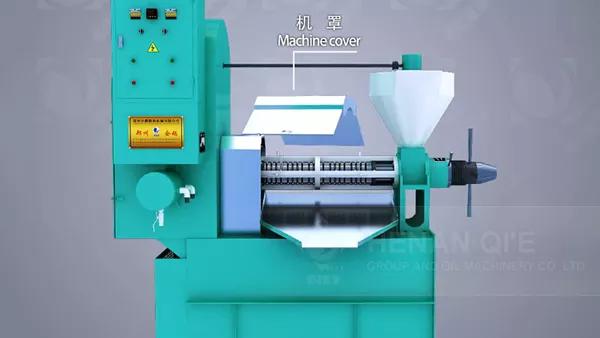

The vertical cake discharging mechanism is a revolutionary design in the field of oil presses. Its working principle is based on a vertical structure that allows the oil cake to be discharged smoothly. This mechanism ensures that the oil can flow out freely during the pressing process, greatly improving the smoothness of oil discharge. In practical applications, oil presses equipped with a vertical cake discharging mechanism can increase the oil extraction rate by up to 15%, reaching an average of 95%.

The segmented cage design is another key innovation. It can effectively prevent the accumulation of oil residue and enhance the structural strength of the oil press. By dividing the cage into segments, the design allows for better flow of oil and reduces the risk of blockage. Tests have shown that oil presses with a segmented cage design can reduce the frequency of blockages by 80%, significantly improving the stability of the equipment. Moreover, the enhanced structural strength can extend the service life of the oil press by up to 3 years.

In addition to performance improvements, the combination of the vertical cake discharging mechanism and segmented cage design also meets industry safety and environmental protection standards. For example, it can reduce the emission of waste oil and residue, which is in line with the requirements of sustainable development. This compliance not only helps enterprises avoid potential legal risks but also enhances their corporate image in the international market.

Let's take a look at the performance comparison between traditional oil presses and those with the new design. In a real - world test, a traditional oil press took 10 hours to process 10 tons of raw materials, with an oil extraction rate of 80%. In contrast, an oil press with a vertical cake discharging mechanism and segmented cage design only took 7 hours to process the same amount of raw materials, with an oil extraction rate of 95%. Many users have also provided positive feedback. One user commented, "Since we replaced our old oil press with the new one, our production efficiency has increased significantly, and the maintenance cost has been greatly reduced."

From a long - term perspective, the new design can bring significant commercial value. By reducing long - term operating costs and improving production efficiency, enterprises can increase their profitability. For example, in a large - scale oil processing plant, the use of this new design can save up to $50,000 in maintenance costs and increase annual profits by up to $200,000.

If you are an equipment procurement decision - maker or a technical director, and you want to learn more about how this design performs in real - world scenarios, click here to get more detailed information.